Shipping on this item will be quoted and billed separately. We will reach out to you to estimate a lead time and make shipping arrangements.

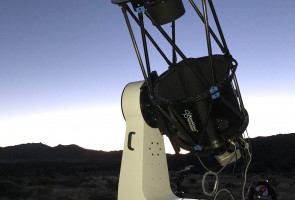

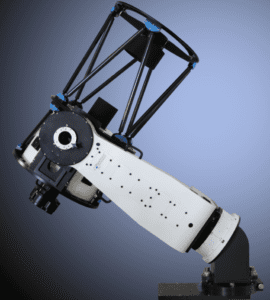

PlaneWave Instruments is proud to introduce its new L-Series direct drive mount system. Offered in Alt-Az or Equatorial configuration. The L-Series comes in three models; the L-350 capable of holding 100 lbs; the L-500 designed for the CDK17/20 that can hold payload of over 200 lbs. The L-600 is ideal for the CDK24 and can hold up to 300 lbs. All mounts are designed and manufactured by PlaneWave Instruments with zero backlash and zero periodic error, virtually silent motion and slew speeds of up to 50 degrees per second!

Description

The L-Series:

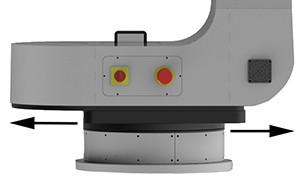

Combines versatility, simplicity and affordability by combining all the technology of our observatory class telescopes into a compact stand-alone mount. In its Alt/Az configuration it is considerably more compact than its equatorial counterpart, allowing a larger telescope to fit in a smaller enclosure. Unlike traditional German Equatorial mounts, there are no meridian flips to deal with, and no large protruding counterweights to create a dangerous hazard in a public observatory. Alt/Az is more intuitive to use and no polar alignment is needed. Besides, it is the way the pros do it! For added flexibility, the L-Series mounts can be installed in either Alt/Az, or equatorial mode with the optional wedge accessory.

L-600 Mount Features:

- Load capacity of 300 lbs (135 kg)

- Direct-drive motors on each axis for smooth, fast, and virtually silent movement of the telescope

- Slew speeds up to 50 degrees per second

- High resolution encoders on each axis for precise positioning

- Zero backlash

- Zero periodic error

- PointXP mount modeling software

- Enclosed electronics

- Through the mount cabling

Checkout our AutoTuner software tutorial below for tuning your L-500 once it is setup and balanced!

Features:

CDK-600 Package – Save $4,000!

| Item Number | Description | Price |

| 240130 | CDK-600(CDK24 / L-600) | $75,000 |

| 600180 | IRF90 Rotating Focuser | $ 4,500 |

| 240901 | EFA, Focuser Accessory Control | $ 1,000 |

| Total | $80,500 |

Specifications

Mount System

| Type | Alt-Azimuth / Equatorial Direct Drive Mount |

| Weight | 338 lbs (153 kg) |

| Max. Load Capacity | 300 lbs (136 kg) |

| Latitude Range | 0 to 90 degrees, Northern and Southern hemispheres |

| Cable Management | Equipment cables can be wired through mount |

Control System

| Control Electronics | PlaneWave Interface dual axis telescope control |

| User Interface | PlaneWave Interface 4 (PWI4) Control Software with integrated PointXP mount modeling software |

| Homing Sensors | Home position sensors are included allowing the mount can find its home position on power up. |

| Slew Rate | 20 degrees per second (standard); 50 degrees per second (maximum), both axes |

| Power Requirement | Accepts 120 to 240 VAC. Supplied with 120 VAC 15A IEC Type B Regulated Power Adapter. |

Motion Control

| Motor Control | Industrial grade brushless motor control system and built in electronics |

| Motor – Azimuth and Altitude | Direct Drive 3 Phase Axial-Flux Torque Motors |

| Encoder – Azimuth and Altitude | 152mm stainless steel encoder ring with reader built into the azimuth and altitude axes. 18,880,000 counts per revolution (0.069 arcsecond resolution). |

| Motor Torque | Approximately 20 ft-lbs continuous; 50 ft-lbs peak |

| Drive Electronics | Industrial grade, off-the-shelf brushless motor drives for each axis with custom designed interface card |

| Telescope Control Software | PlaneWave Interface (PWI4). Incorporates PointXP mount modeling software by Dave Rowe. Provides HTTP and ASCOM control interfaces. |

System Performance

| Pointing Accuracy | <10 arcsecond RMS with PointXP Model |

| Pointing Precision |

2 arcseconds at sidereal velocity |

| Tracking Accuracy |

< 0.3 arcseconds over a 5 minute period at sidereal velocity |

| System Natural Frequency | 10 Hz or greater |

Included Items

| Hardware | Six 1/2-13 x 1 1/4″ socket head cap screws to bolt the mount to the pier, or wedge

Six 1/2-13 washers One extended length shoulder bolt for RA axis to EQ wedge alignment |

| One 16′ USB cable | To connect the mount to the observatory control computer |

| One 120VAC power cable | To provide power to the mount |

| Standard Allen Key set | For tightening bolts used on the mount |

| Flashdrive | Contains PWI4 software for mount control and instructions for installation |

| 3/8 Socket | Used for operating the RA balance leadscrew on the mount |

| Gamepad | Used for control of the mount tracking speeds for visual observing |

Buy risk-free: When it’s time to trade up you’ll get the most value for your used gear.

In Stock

In Stock